Quality

Supplier Management

At ACE ERA, quality is our commitment and we have a comprehensive supplier management system in place to ensure the quality, integrity and safety of electronic components, including:

Supplier Level

Level 1:

Original Manufacturer, Category Distributor, Franchised DistributorLevel 2:

OEM, ODM, EMS factoriesLevel 3:

Qualified suppliers with third-party certificationLevel 4:

Unqualified supplier (Black list)

Suppliers Audit

● Use external resources to investigate new supplier history

● Conduct extensive audits of new suppliers, including trade references

● Qualified new suppliers will be added to the approved supplier list

Supplier Maintenance

● SAP system that automatically monitors supplier performance and activity

● Liaise with sales, purchasing, quality control, customer and other related departments on supplier status

● Removal from approved supplier list due to excessive or serious quality problems and add to the black list

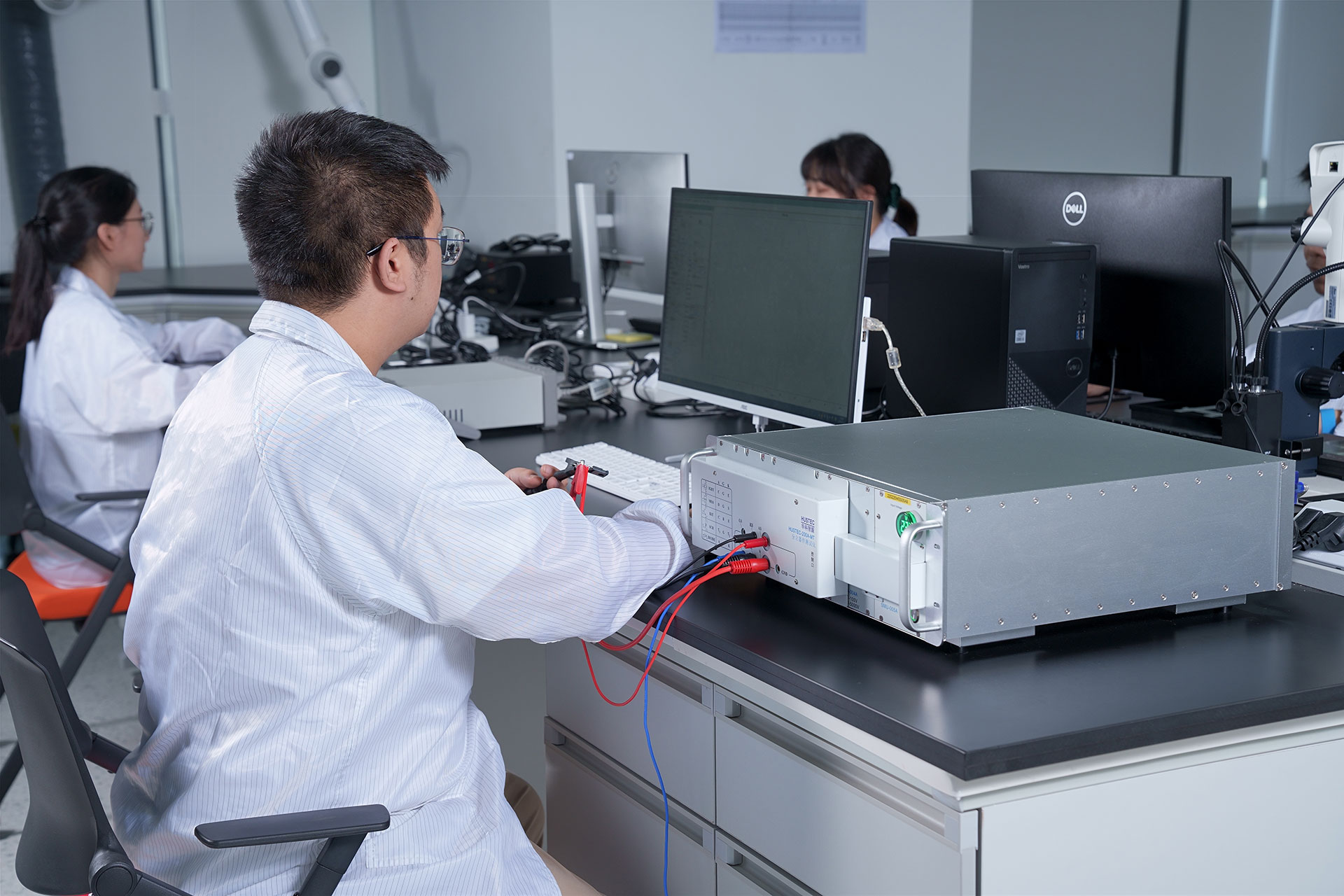

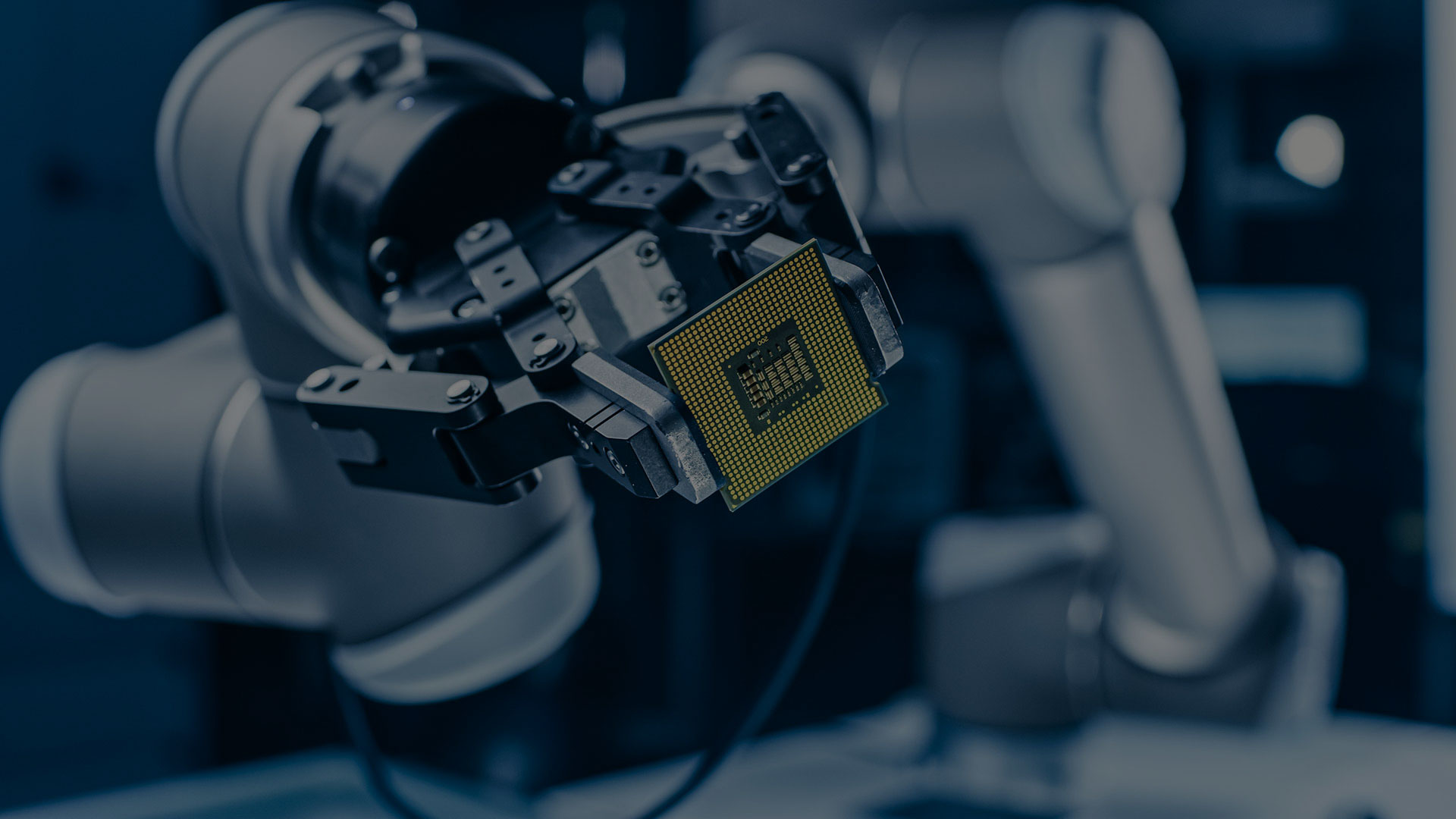

Testing

Laboratory

ACE ERA is one of the few independent distributors and has its own testing laboratory and established quality control systems. Each product is inspected and verified by ACE ERA well-trained and experienced engineers, and a detailed inspection process including microscopic inspection, digital measurement, and full image collection is processed and archived.

Quality Inspection Procedures

Strict Process

The strict quality inspection process is an important part of ACE ERA quality control system, we have professional testing equipment, experienced QC engineers, a rigorous and responsible work attitude – all of which can ensure that the quality of the products we deliver is what our customers want.

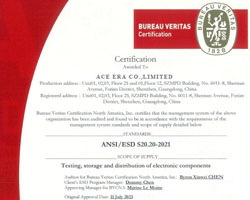

Third-Party Laboratory

ACE ERA cooperates with third-party labs (Whitehorse and CECC) for further quality control requirements. This accomplishes a guarded, multilayer, stepped process to ensure that products are 100% genuine.

Quality Assurance

Multi-level, quality inspections to avoid fake and shoddy products. We pride ourselves on selling quality products and our commitment to quality.

Inspection Procedures

-

Check packaging conditions, and verify label source and label information.1Packaging and Documentation Inspection

-

2Check marking and part orientation consistency.General

Inspection -

3Check for any inconsistency and defects on products indicating refurbishment, counterfeit or poor reliability.Visual

Inspection -

4Reveal remarking by chemical solvent and mechanical scrape means.Remarking and

Resurfacing

Tests -

5Verify package size by measuring product dimensions and comparing them with manufacturer specifications.Dimension

Measurement -

6Detect the content of restricted substances (Pb, Cd, Hg, total Br, total Cr) in electronic & electrical parts.XRF

Detection -

7Verify that the internal structure or die construction is identical with samples or database.X-Ray

Inspection -

8Verify whether static parameters are within manufacturer specifications.Electrical

Performance

Test -

9Verify the solderability of components leads and terminations by Dipping.Solderability

test -

10Decap the device and verify authenticity by observing the die marking and comparing it with golden sample or those in the database.Decapsulation

-

11After the completion of inspection, undamaged samples are placed back into their original carriers and outer packaging, and sealed securely.Packaging

-

12Products that pass the quality inspection are safely transferred to our warehouse.Secure

Warehousing

Warehouse and Shipping

Electronic components are sensitive items with high demands for storage/packaging/delivering environments. ACE ERA strictly complies with the original preservation environmental standards for materials of all levels.

Packaging

Anti-static packaging/label

Temperature

Constant temperature control

Information

Files for each customer with information of packaging demands and labeling

Humidity

Humidity degree control

Transportation

Files for each customer with information of transportation demands to find the fastest, safest and most economical way of transportation